Item Code: | KG-1805 |

Color: | Green |

Standard: | CE, EN 374 |

Type: | AQL 0.65, Chemo-resistant |

Packaging: | 100 pcs/box,10 boxes/carton |

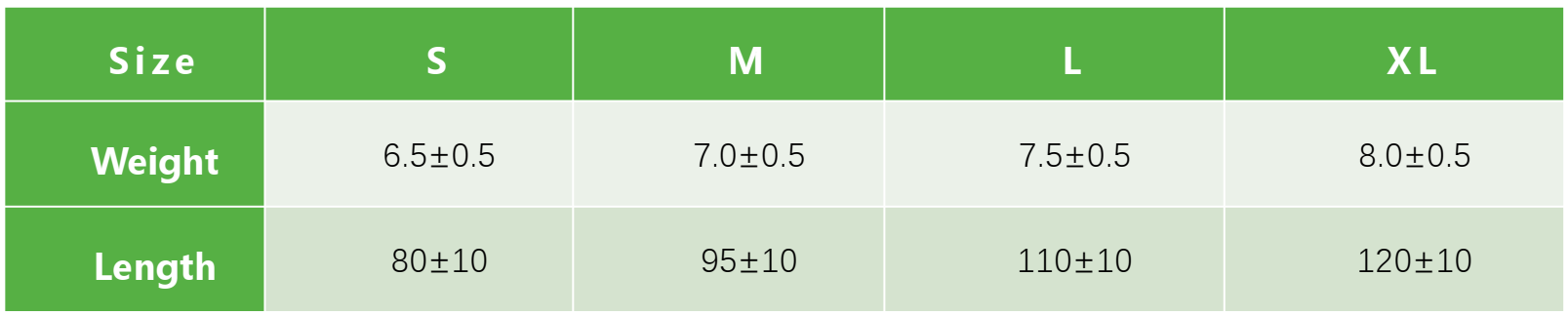

Size: | S, M, L, XL |

Application

Chemo-resistant Nitrile Gloves (KG-1805) is an advanced chemical splash protection glove. Made of special formula and process, it has excellent chemical splash protection and tear resistance. Widely used in laboratory, life science, manufacturing food processing, manufacturing and so on.

Features

●Excellent splash protection against chemicals, effectively preventing chemical reagent permeation.

●High strength, abrasion resistance, puncture resistance, soft and comfortable fit, reducing fatigue.

●Smooth donning, powder-free and silicone oil-free, non-irritating and non-sensitizing to skin.

●Textured finger for enhanced tactile sensitivity and grip, ensuring precise and agile manipulation.

● Multi-dipping process ensures extremely low pinhole rate and strong resistance to chemical permeation.

Technical Specifications

●Length (mm/inches): ≥240 mm / 9.5 inches

●Wrist Thickness (mm): ≥0.100 mm / 4 mils

●Palm Thickness (mm/mils): ≥0.125 mm / 5 mils

●Fingertip Thickness (mm/mils): ≥0.150 mm / 6 mils

●Needle Hole Rate: AQL 0.65

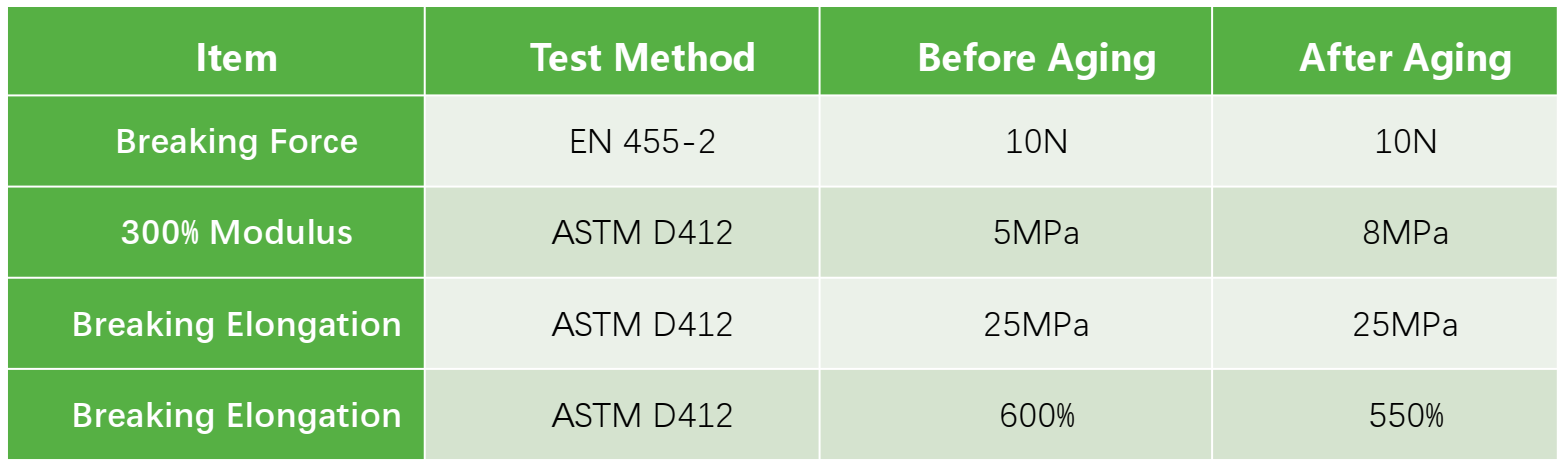

Mechanical Properties

Kingfa Chemo-resistant Nitrile Gloves feature enhanced abrasion resistance and tear strength through optimized vulcanization systems. This makes them more durable in high-frequency and rough environments, suitable for heavy industries and high-friction applications.

Abrasion test data indicates that the chemical-resistant nitrile gloves can withstand up to 2,000 revolutions before showing signs of wear, while ordinary nitrile gloves typically begin to sustain damage around 500 revolutions on average.

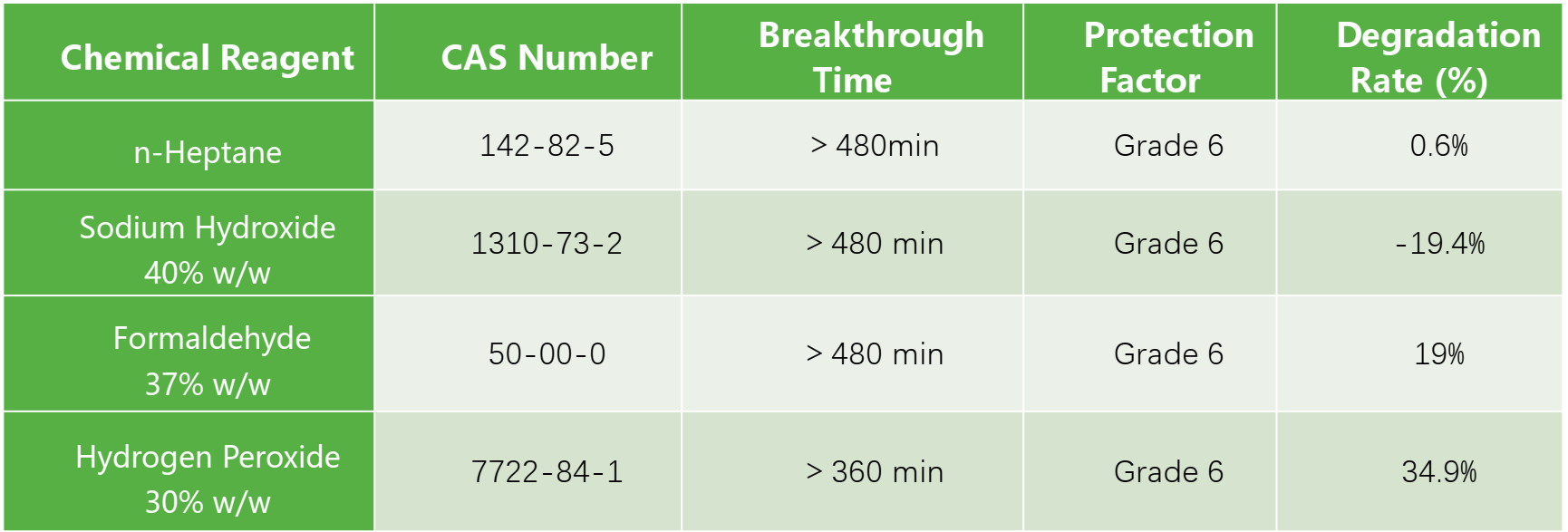

Chemical Permeability and Degradation

Chemo-resistant Nitrile Gloves, employing a special latex formula and vulcanization system, exhibit superior permeation resistance. They are ideal for environments with corrosive chemicals like strong acids, bases, and organic solvents.

Tests show that these gloves can resist permeation by sodium hydroxide, formaldehyde, and n-heptane for 480 minutes each, and by hydrogen peroxide for 360 minutes, far exceeding ordinary nitrile gloves in protective capability.

Test Method: EN 16523-1:2015+A1:2018

Kingfa has established a testing platform for assessing the chemical permeation performance of gloves based on the test methods EN 16523-1:2015+A1:2018. This platform is used to evaluate the requirements for glove permeation performance in different application scenarios, thereby providing safer and more effective protection solutions for wearers.

Standard Quality

●EN 16523-1:2015+A1:2018

●EN ISO 21420:2020

●EN ISO 374-1:2016+A1:2018,

●EN 374-2:2019

●EN 374-4:2019

●EN 374-5:2016

Logistic Information

●Packaging: 100 pcs/box, 10 boxes/carton

OEM Services

●Product design and development

●Flexible & timely manufacture

●Quality control and regulatory compliance

●Cost effective with product assurance

●Packaging & shipment

●Technical support

Manufacturing Accreditations

●ISO 9001 Quality Management System

●ISO 13485 Quality Management System

●QSR820 FDA Quality System Requirements

Application

Chemo-resistant Nitrile Gloves (KG-1805) is an advanced chemical splash protection glove. Made of special formula and process, it has excellent chemical splash protection and tear resistance. Widely used in laboratory, life science, manufacturing food processing, manufacturing and so on.

Features

●Excellent splash protection against chemicals, effectively preventing chemical reagent permeation.

●High strength, abrasion resistance, puncture resistance, soft and conformable fit, reducing fatigue.

●Smooth donning, powder-free and silicone oil-free, non-irritating and non-sensitizing to skin.

●Textured finger for enhanced tactile sensitivity and grip, ensuring precise and agile manipulation.

● Multi-dipping process ensures extremely low pinhole rate and strong resistance to chemical permeation.

Technical Specifications

●Length (mm/inches): ≥240 mm / 9.5 inches

●Wrist Thickness (mm): ≥0.100 mm / 4 mils

●Palm Thickness (mm/mils): ≥0.125 mm / 5 mils

●Fingertip Thickness (mm/mils): ≥0.150 mm / 6 mils

●Needle Hole Rate: AQL 0.65

Mechanical Properties

Kingfa Chemo-resistant Nitrile Gloves feature enhanced abrasion resistance and tear strength through optimized vulcanization systems. This makes them more durable in high-frequency and rough environments, suitable for heavy industries and high-friction applications.

Abrasion test data indicates that the chemical-resistant nitrile gloves can withstand up to 2,000 revolutions before showing signs of wear, while ordinary nitrile gloves typically begin to sustain damage around 500 revolutions on average.

Chemical Permeability and Degradation

Chemo-resistant Nitrile Gloves, employing a special latex formula and vulcanization system, exhibit superior permeation resistance. They are ideal for environments with corrosive chemicals like strong acids, bases, and organic solvents.

Tests show that these gloves can resist permeation by sodium hydroxide, formaldehyde, and n-heptane for 480 minutes each, and by hydrogen peroxide for 360 minutes, far exceeding ordinary nitrile gloves in protective capability.

Test Method: EN 16523-1:2015+A1:2018

Kingfa has established a testing platform for assessing the chemical permeation performance of gloves based on the test methods EN 16523-1:2015+A1:2018. This platform is used to evaluate the requirements for glove permeation performance in different application scenarios, thereby providing safer and more effective protection solutions for wearers.

Standard Quality

●EN 16523-1:2015+A1:2018

●EN ISO 21420:2020

●EN ISO 374-1:2016+A1:2018,

●EN 374-2:2019

●EN 374-4:2019

●EN 374-5:2016

Logistic Information

●Packaging: 100 pcs/box, 10 boxes/carton

OEM Services

●Product design and development

●Flexible & timely manufacture

●Quality control and regulatory compliance

●Cost effective with product assurance

●Packaging & shipment

●Technical support

Manufacturing Accreditations

●ISO 9001 Quality Management System

●ISO 13485 Quality Management System

●QSR820 FDA Quality System Requirements