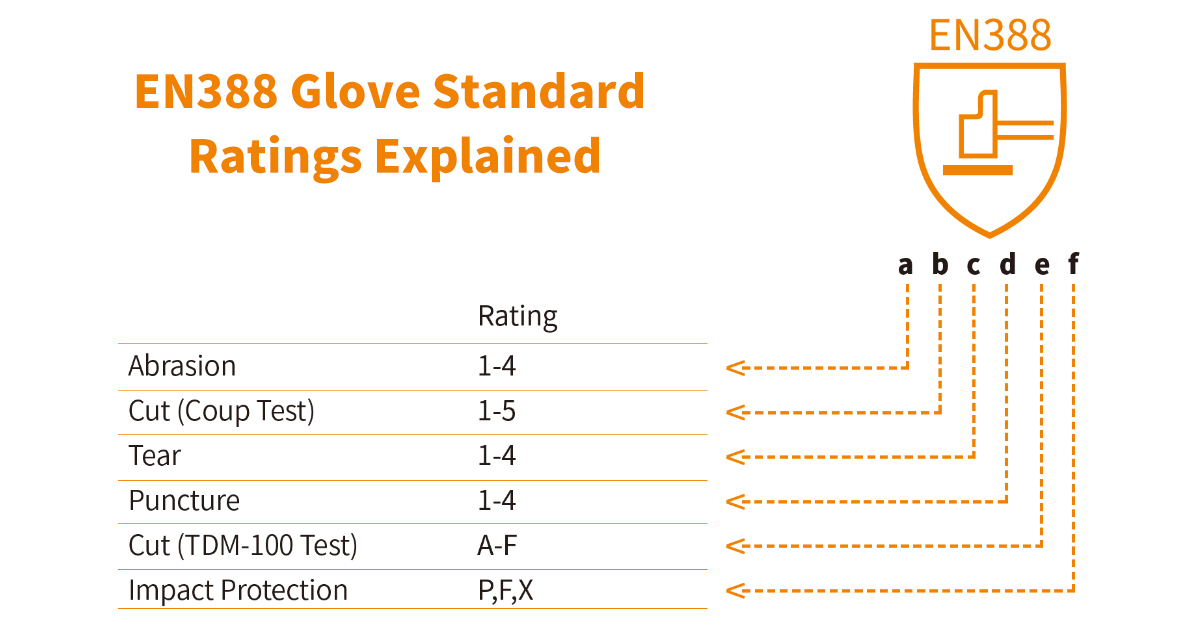

In March 2020, the EU published a new standard :EN ISO 21420:2019 General Requirements and Test Methods for Protective Gloves. The manufacturer of protective gloves must ensure that the material used in the production of the product does not affect the health of the operator. The new standard replaces the previous EN 420 standard. In addition, EN388 is one of the European standards for industrial protective gloves, and version EN388:2003 was approved by the European Committee for Standardization (CEN) on 2 July 2003. EN388:2016 was published in November 2016, replacing EN388:2003, and was revised in 2018 with a supplementary version EN388:2016+A1:2018.

Relevant standards for protective gloves:

●EN388:2016 Mechanical Standard for Protective gloves

●EN ISO 21420:2019 Protective gloves - General requirements and test methods

●EN 407 Standard for fire and thermal performance gloves

●EN 374 Protective gloves - Resistance to chemical osmosis

●EN 511 Regulatory standard for cold and low temperature resistant gloves

●EN 455 Protective Gloves Impact Cut protection

Test methods for protective gloves

In order to protect the safety of consumers and avoid the loss of dealers caused by product recall due to quality problems, all protective gloves exported to EU countries must pass the following inspection:

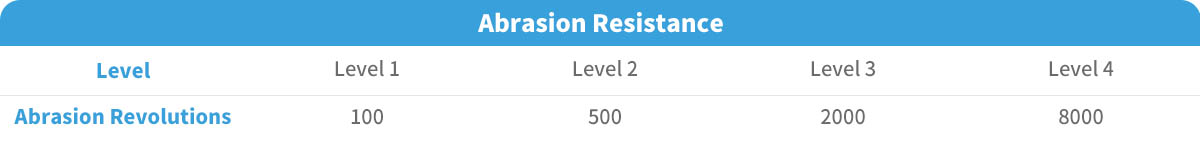

1.1 Abrasion resistance

Take the palm material of the glove, wear it with sandpaper under a fixed pressure, and calculate the number of revolutions of a hole in the wear material. According to the table below, the higher the number of revolutions from 1 to 4, the better the wear resistance.

1.2 Blade Cut Resistance-Coupe

By moving a rotating circular blade horizontally back and forth across the glove sample, the number of blade turns is recorded as the blade penetrates the sample. The same blade was used to test the number of cutting laps of standard canvas before and after sample test. The cutting resistance of the sample was determined by comparing the wear degree of the blade during sample and canvas test. The cutting resistance was divided into 1-5 levels, which were represented by 1-5 numbers.

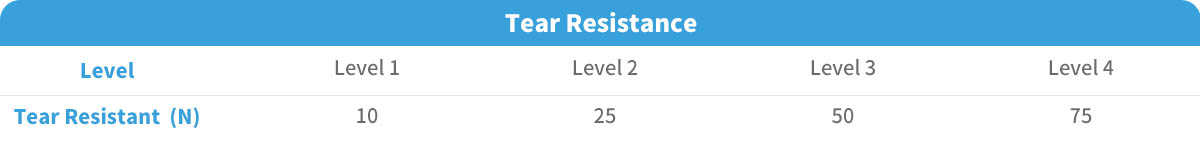

1.3 Tear Resistance

The material in the palm of the glove is torn by a tension device. The tear resistance level of the product is determined by calculating the force required to tear, which is represented by a number between 1 and 4. The higher the force value, the better the tearing resistance. (Considering the properties of the textile material, the warp and weft, tear test includes both transverse and longitudinal tests.)

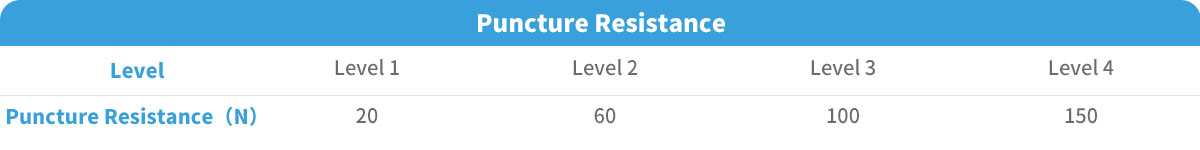

1.4 Puncture Resistance

A standard needle is used to Pierce the palm material of the glove, and the force used to Pierce the glove is calculated to determine the level of puncture resistance of the product, as indicated by a number between 1 and 4. The higher the force value, the better the puncture resistance.

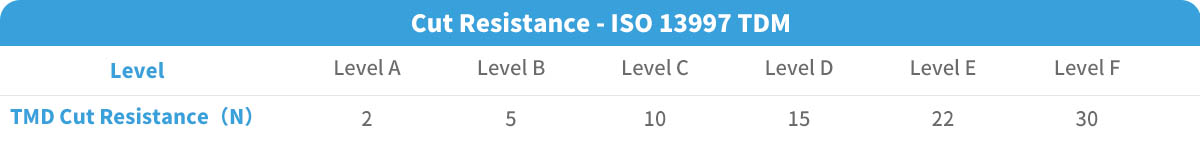

1.5 Cut Resistance - ISO 13997 TDM

TDM cutting test is to use the blade to cut the glove palm material at a constant speed, test the walking length of the blade when cutting through the sample under different loads, and calculate (slope) with a precise mathematical formula to find out how much force should be applied to make the blade cut through the sample when walking 20mm.

TDM cutting test is to use the blade to cut the glove palm material at a constant speed, test the walking length of the blade when cutting through the sample under different loads, and calculate (slope) with a precise mathematical formula to find out how much force should be applied to make the blade cut through the sample when walking 20mm.

This test is A new addition to EN388:2016. The result grade is indicated by A-F, with F being the highest grade. Compared to EN 388:2003 coupe tests, TDM tests can provide more accurate indicators of working anti-cutting performance.

1.6 Impact resistance(EN 13594)

This is an optional test. If the gloves have been tested for impact protection, this information is given by the letter P as the sixth and final symbol. Without P, gloves have no impact protection.

The EN 388:2016 standard helps workers determine which gloves have the appropriate level of protection in the working environment to prevent mechanical risks. For example, construction workers may often encounter wear hazards and need to choose gloves with higher wear resistance, while metalworking workers need to protect against cutting tool injuries or scratches on the sharp edges of metal, which requires gloves with a higher cutting resistance rating.