After a series of processes such as hand mold cleaning, latex impregnation, and crimping, gloves require a final step of surface treatment before they can be worn. The most common surface treatments are powder application, chlorinntion and polymer coating.

The chlorination procedure is one of the powder-free processes that first appeared in the 1980s in the production of latex gloves. As a mature product process, the chlorination has been widely used nowadays especially in the production of nitrile gloves.

What is chlorination for disposable gloves?

After the gloves are molded in the hand mold, the chlorination is needed before the gloves are removed from hand mold.

Chlorination is process that uses a chlorine solution to rinse gloves. Generally, chlorine solutions with a concentration of approximately 300-800 ppm are prepared using liquid chlorine dissolved in water

During this process, the solution reacts with the latex or rubber by cyclization and cross-linking, forming a barrier layer on the inner surface of the glove. When used on latex gloves, the chlorination process also reduces the amount of latex proteins.

As the chlorination process has matured, most glove manufacturers perform double chlorinations on their gloves.

The single-chlorinated forms a coating on the inner surface of the glove to make it easier for personnel to wear.And double-chlorinated gloves are chlorinated both on internal and external surfaces during the process.

Chlorination on the outer surface prevents gloves from sticking to each other, which is the most obvious disadvantage of single-chlorinated gloves.

Elemental chlorine, chlorine ions, and chlorine compounds derived from the double-chlorinated process will remain on the surface of the gloves. Once these substances come into contact with electronic components,it is easy to cause short circuiting, erosion or metal ionization of the electronic components and there is a high risk of products contamination. Therefore, after chlorine washing, the gloves are usually neutralized and further washed to remove surface residues.

Advantages of chlorination

①In the case of latex gloves, the chlorination procedure reduces the amount of latex proteins inside the glove, thus reducing allergic reactions caused by latex proteins.Besides,it also makes the gloves softer and more durable.

②Chlorination is a powder-free process in which bacteria and viruses are more thoroughly killed, effectively ensuring the hygiene and safety of gloves.

③The most prominent advantage of the chlorine washing process is that it makes gloves more convenient to wear. The raw materials used in gloves are basically sticky and have high friction, which makes gloves difficult to wear.

Chlorination produces a barrier layer on the surface of the glove to replace the raw material of the glove and the hands touch, which helps to reduce friction and make wearing smoother.Further more, chlorine-washed gloves are softer and more comfortable to wear.

Disadvantages of chlorination

①The chlorination procedure possibly alter some of the functions of gloves, such as grip properties and the appearance of color.There is also a possible disvantage that chlorination maybe reduces the shelf life of products.

②Chlorined gloves are usually more expensive than other usual disposable gloves.

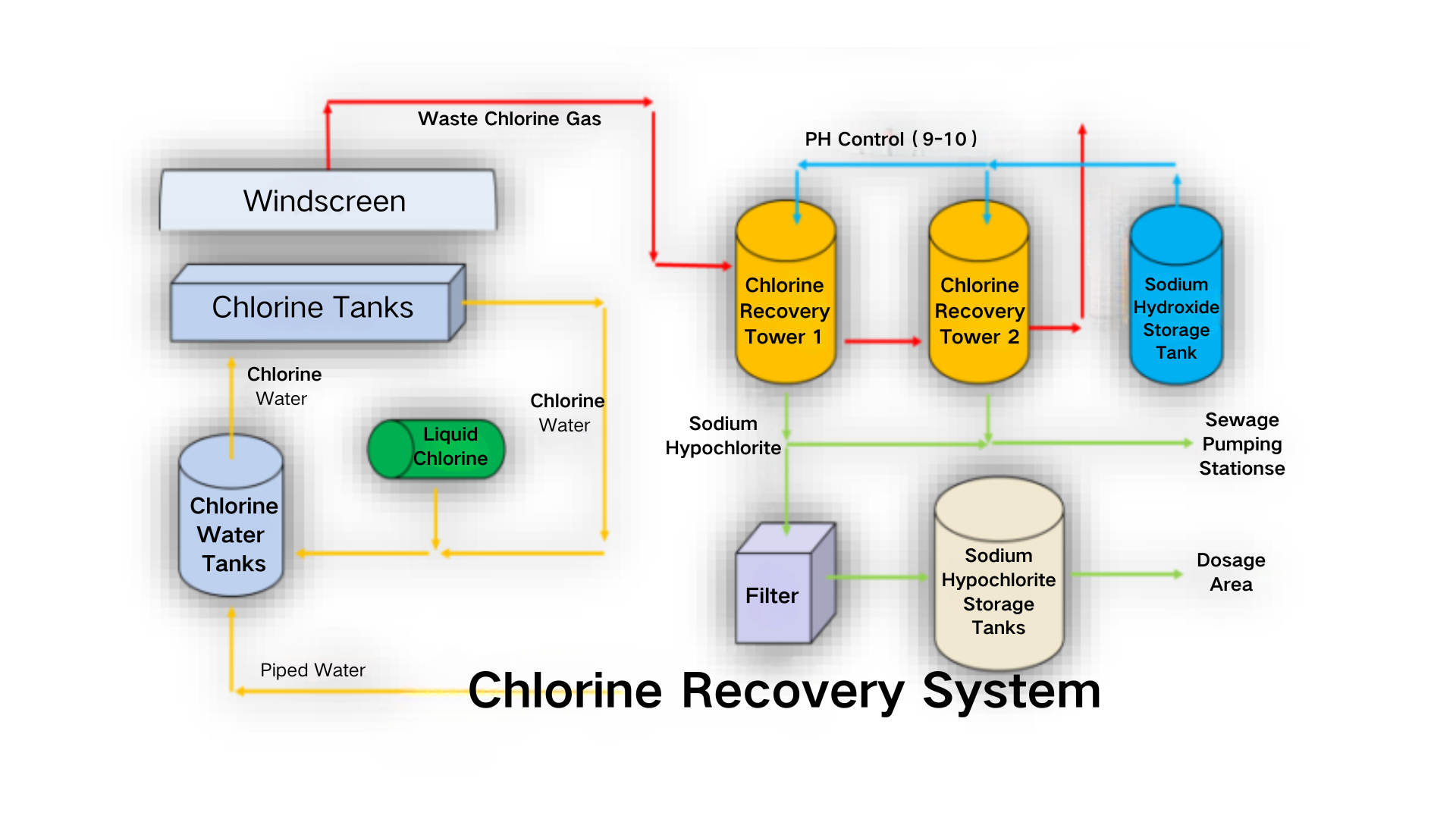

③ Waste water from the chlorination process may cause environmental pollution if it is not treated properly. To address this issue, Kingfa Medical has established a comprehensive chlorine recovery system. The waste chlorine gas after use is recycled into specialized containers. Afterwards, the chlorine gas is purified or reused by means of filtration and reaction with other chemicals. This system not only realizes the recycling of resources, but also effectively reduces the degree of environmental pollution.