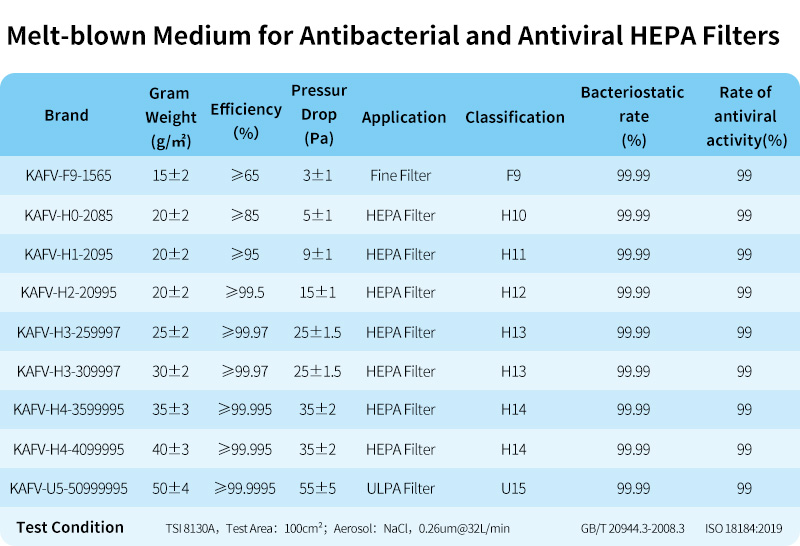

Type: | Antibacterial&Antiviral HEPA Melt-blown Filter Media |

Level: | F9、H10、H11、H12、H13、H14、U15 |

Standard: | EN779、EN1822、ISO 18184 |

Bacteriostatic Rate: | 99.99% |

Antiviral Activity Rate: | 99% |

Shelf-life: | Over 2 years |

Intended Use

KINGFA Antibacterial&Antiviral HEPA Melt-blown Filter Media is made of polypropylene, and its fiber diameter can reach 0.5-5 microns. Its unique wick structure of the ultra-fine fibers can increase the number and surface areas of fiber per unit, which enables the fabric to possess superb filtering, shielding, thermal-insulating, and oil-absorbing properties. The material has a bacteriostatic rate of over 99.99% against Escherichia coli, Staphylococcus aureus, and Klebsiella pneumoniae, and an antiviral activity rate of more than 99% against the H1N1 virus. It is widely used in cabin air filters for automobiles, air purifiers for household and similar purposes, protective masks, medical masks, fresh air systems, etc.

Features

●Antibacterial & Antiviral Properties: The material has in-situ modification that provides a high bacteriostatic rate of over 99.99% against Escherichia coli, Staphylococcus aureus, and Klebsiella pneumoniae, as well as a high antiviral activity rate of over 99% against the H1N1 virus.

●High Filtration Efficiency:The melt-blown medium has a unique wick structure with ultra-fine fibers that increase the number and surface areas of fibers per unit, resulting in superb filtering performance against particles as small as 0.3 microns.

●Low Resistance: The material has low resistance to air flow, ensuring efficient air filtration while maintaining a comfortable air flow rate.

●Charge Stability: The three-dimensional mesh fiber structure of the melt-blown medium provides good uniformity and charge stability, ensuring that the material maintains its filtration performance over time.

●Versatility: The melt-blown medium is widely used in various applications, including automobiles-cabin air filters, air purifiers for household and commercial use, protective masks, medical masks, and fresh air systems.

Quality Standards

●Standard: EN779:2012、EN1822:2009、ISO 18184:2019

●Product Safety: ROSH、REACH

Material

Polypropylene、Antioxygen、Electrified agent、Zinc oxide、Silver sodium zirconium phosphate

Product Specifications

Technical Advantage

●In-situ Modification Technology:This technology allows for the integration of antibacterial and antiviral functions into the material, increasing its effectiveness in intercepting 0.3um particles and inhibiting the reproduction of bacteria and viruses.

●Molecular Weight Controllable Regulation Technology: This technology enables the regulation of the molecular weight of the material, resulting in enhanced filtration efficiency.

●Friction Electret Technology: This technology creates an electrostatic charge in the material, which helps to capture small particles and improve the filter's overall efficiency.

●Superfine Nanofiber Controllable Technology: This technology produces superfine fibers in the material, increasing the number and surface area of fibers per unit and enhancing the filter's filtering, shielding, thermal-insulating, and oil-absorbing properties.

●Low Resistance: The combination of the above technologies results in a material with high efficiency and low resistance, reducing the burden on air circulation systems and improving energy efficiency.

Manufacturing Accreditations

●ISO 13485:2006 Medical Device Quality Management System Certification

●ISO 9001:2015 Quality Management System

●EPA Company Number 99922

OEM Services

●Product design and development

●Flexible & timely manufacture

●Quality control and regulatory compliance

●Cost effective with product assurance

●Packaging & shipment

●Technical support

Intended Use

KINGFA Antibacterial&Antiviral HEPA Melt-blown Filter Media is made of polypropylene, and its fiber diameter can reach 0.5-5 microns. Its unique wick structure of the ultra-fine fibers can increase the number and surface areas of fiber per unit, which enables the fabric to possess superb filtering, shielding, thermal-insulating, and oil-absorbing properties. The material has a bacteriostatic rate of over 99.99% against Escherichia coli, Staphylococcus aureus, and Klebsiella pneumoniae, and an antiviral activity rate of more than 99% against the H1N1 virus. It is widely used in cabin air filters for automobiles, air purifiers for household and similar purposes, protective masks, medical masks, fresh air systems, etc.

Features

●Antibacterial & Antiviral Properties: The material has in-situ modification that provides a high bacteriostatic rate of over 99.99% against Escherichia coli, Staphylococcus aureus, and Klebsiella pneumoniae, as well as a high antiviral activity rate of over 99% against the H1N1 virus.

●High Filtration Efficiency:The melt-blown medium has a unique wick structure with ultra-fine fibers that increase the number and surface areas of fibers per unit, resulting in superb filtering performance against particles as small as 0.3 microns.

●Low Resistance: The material has low resistance to air flow, ensuring efficient air filtration while maintaining a comfortable air flow rate.

●Charge Stability: The three-dimensional mesh fiber structure of the melt-blown medium provides good uniformity and charge stability, ensuring that the material maintains its filtration performance over time.

●Versatility: The melt-blown medium is widely used in various applications, including automobiles-cabin air filters, air purifiers for household and commercial use, protective masks, medical masks, and fresh air systems.

Quality Standards

●Standard: EN779:2012、EN1822:2009、ISO 18184:2019

●Product Safety: ROSH、REACH

Material

Polypropylene、Antioxygen、Electrified agent、Zinc oxide、Silver sodium zirconium phosphate

Product Specifications

Technical Advantage

●In-situ Modification Technology:This technology allows for the integration of antibacterial and antiviral functions into the material, increasing its effectiveness in intercepting 0.3um particles and inhibiting the reproduction of bacteria and viruses.

●Molecular Weight Controllable Regulation Technology: This technology enables the regulation of the molecular weight of the material, resulting in enhanced filtration efficiency.

●Friction Electret Technology: This technology creates an electrostatic charge in the material, which helps to capture small particles and improve the filter's overall efficiency.

●Superfine Nanofiber Controllable Technology: This technology produces superfine fibers in the material, increasing the number and surface area of fibers per unit and enhancing the filter's filtering, shielding, thermal-insulating, and oil-absorbing properties.

●Low Resistance: The combination of the above technologies results in a material with high efficiency and low resistance, reducing the burden on air circulation systems and improving energy efficiency.

Manufacturing Accreditations

●ISO 13485:2006 Medical Device Quality Management System Certification

●ISO 9001:2015 Quality Management System

●EPA Company Number 99922

OEM Services

●Product design and development

●Flexible & timely manufacture

●Quality control and regulatory compliance

●Cost effective with product assurance

●Packaging & shipment

●Technical support