Knowledge

KINGFA Solutions

Hand Protection

Respiratory Protection

Environmental Solutions

Industrial Protection

Filtering Material

Protective Apparels

Laboratory Solutions

Email:

kingfamed@kingfa.com

Address:

No.33 Kefeng Road, Science City, Guangzhou, Guangdong Province, China, 510663

INQUIRY

Knowledge

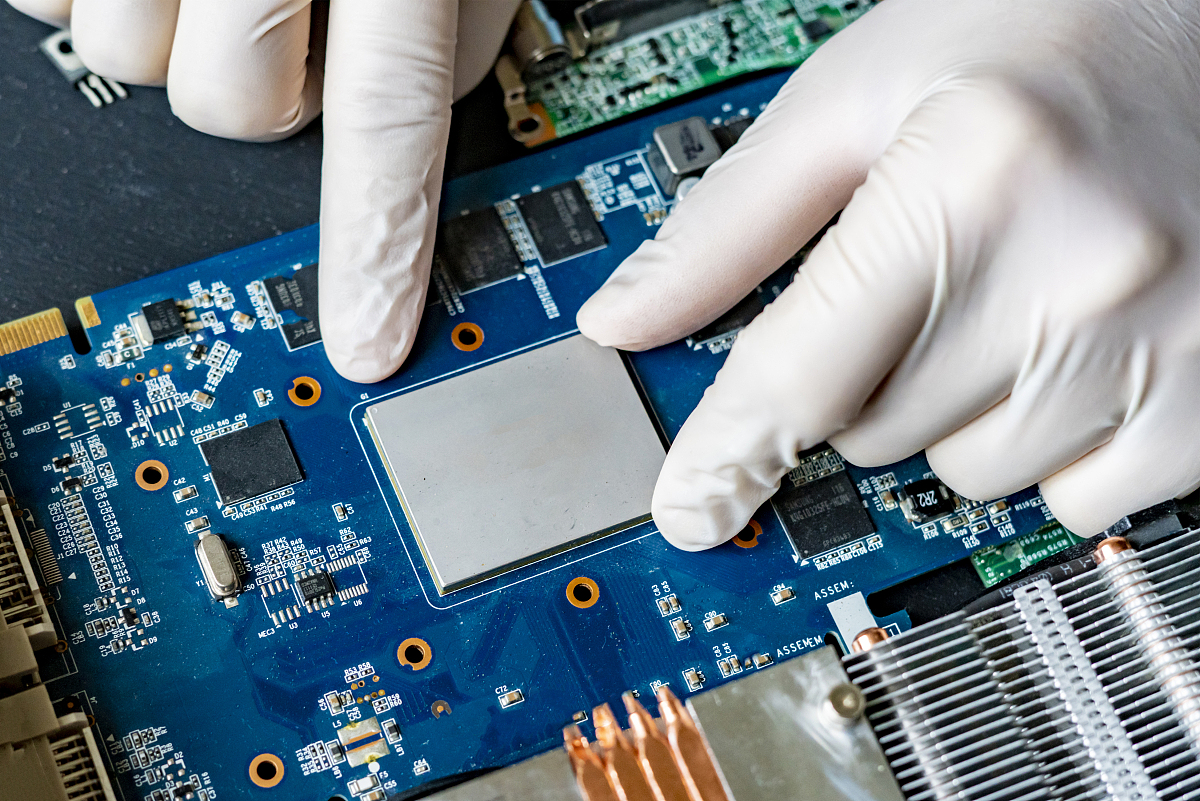

Why cleanroom nitrile gloves are suitable for the electronics industry?

As electronic components become more sensitive and production cleanliness standards rise, gloves help maintain product quality by minimizing contamination and reducing static discharge risks.Among them, cleanroom gloves stand out in a crowd of gloves, considered the most suitable for the electronics industry gloves.

READ MORE

What Make 28 Consecutive Successful Tests of KINGFA MEDICAL's Face Masks in Europe?

Kingfa Medical, established in 2020, entered the face mask production industry with a focus on innovative materials and high-quality standards. Our masks exceed global certification requirements, with advanced filtration efficiency, low resistance, and enhanced breathability. With proprietary technologies ensuring superior protection, comfort, and reliability, Kingfa Medical definitely becomes a trusted choice for governments and leading enterprises worldwide.

READ MORE

A Complete Guide to Glove Selection and Data Interpretation

When choosing gloves, we are often puzzled by some data,which are often closely related to the quality and characteristics of the gloves. Interpreting common glove data helps to choose more suitable gloves.

READ MORE

The Impact of HEPA Filtration on Indoor Air Quality and Psychological Well-Being

Experience the difference with HEPA filters, capturing 99.97% of airborne particles — from dust and pollen to bacteria and viruses. Perfect for homes and offices, they reduce allergens, improve air quality, and give you peace of mind with every breath.

READ MORE

What is ASTM F2100-21 Standard? A Guide to Mask Certification Terms in the US Market

The ASTM F2100-21 standard defines the performance requirements for medical face masks in the US, ensuring their quality and safety. It covers key tests such as fluid resistance, bacterial filtration efficiency (BFE), and particle filtration efficiency (PFE).

READ MORE

From Production to Inspection: KINGFA Medical Gloves' Proven Quality Testing Workflow

As one of the largest glove suppliers in the world, KINGFA MEDICAL puts quality and safety at the forefront of glove production. In order to ensure the performance of our gloves, we have developed a set of efficient quality control processes.

READ MORE

SUCCESS

You've successfully subscribed to our newsletter.

OK